316L Stainless Steel

- Overview of 316L Stainless Steel

316L stainless steel is a low-carbon variant of 316 stainless steel, renowned for its superior corrosion resistance, strength, and versatility. It is primarily composed of chromium, nickel, and molybdenum, which contribute to its exceptional ability to withstand harsh environmental conditions. This makes it an ideal material for architectural applications that demand both aesthetic appeal and long-lasting durability. - Importance of Material Selection in Architectural Design

In modern architecture, the selection of materials is crucial as it influences not only the aesthetic of a building but also its functionality, sustainability, and longevity. Stainless steel, especially 316L, has risen to prominence due to its ability to meet these diverse needs. It is a perfect fit for both exterior and interior applications, ensuring a harmonious blend of form and function.

Durability and Corrosion Resistance

- Superior Corrosion Resistance

316L stainless steel is highly resistant to corrosion, even in highly corrosive environments such as coastal areas or industrial zones. This resistance comes from the addition of molybdenum, which enhances its resistance to chloride-induced corrosion. The passive oxide layer on the surface of 316L stainless steel forms a protective barrier, preventing rust and oxidation. Unlike iron or aluminum, 316L does not degrade in humid or salty conditions, making it the go-to material for projects in environments that face challenging weather conditions. - Ideal for Challenging Environments

In areas exposed to extreme weather, such as coastal regions, marine environments, or urban areas with high pollution levels, 316L stainless steel stands up to the test. For instance, when used in facades or cladding systems, it will not discolor, corrode, or weaken over time, ensuring that the structure remains aesthetically pleasing and structurally sound. - Довговічність і низькі витрати на обслуговування

Due to its remarkable corrosion resistance, 316L stainless steel requires minimal maintenance, which is a significant advantage in both residential and commercial applications. While other materials like wood or iron require frequent maintenance and occasional replacements, 316L stainless steel maintains its strength, appearance, and integrity over several decades, thus minimizing long-term upkeep costs.

Aesthetic Appeal in Architectural Design

- Modern and Sleek Appearance

One of the primary reasons architects and designers opt for 316L stainless steel is its sleek, modern appearance. The material’s polished, reflective surface brings a high-end, industrial touch to any architectural design. Whether used in exterior facades, staircases, or decorative features, stainless steel adds a sophisticated, timeless quality to the structure. - Універсальність дизайну

316L stainless steel is incredibly versatile when it comes to design. It can be shaped into various forms, such as smooth curves, angular lines, or intricate patterns, depending on the architectural requirements. Whether it’s for structural elements like handrails and support beams or decorative panels and facades, 316L stainless steel adapts easily to the needs of the design. Additionally, it offers various finishes, including brushed, matte, and mirror finishes, providing endless possibilities for design creativity. - Complementing Other Materials

316L stainless steel complements a wide range of materials, including glass, wood, stone, and concrete. For example, a combination of stainless steel handrails with glass balustrades can create an open and airy feel, allowing unobstructed views, while adding elegance to a modern setting. This ability to pair seamlessly with other materials makes 316L stainless steel an ideal choice for a wide variety of design aesthetics.

Strength and Structural Integrity

- High Strength-to-Weight Ratio

One of the standout features of 316L stainless steel is its high strength-to-weight ratio. This means that architects can use thinner materials without compromising the strength or stability of the structure. Whether used in columns, beams, or facades, 316L stainless steel ensures a reliable load-bearing capacity while reducing the overall weight of the building, which is especially valuable in large-scale projects. - Enhanced Safety and Reliability

The tensile strength of 316L stainless steel ensures that it can withstand stress, pressure, and heavy loads. It is highly resistant to bending, warping, and cracking, making it a reliable material for safety-critical components such as staircases, handrails, and balustrades. Its strength also makes it suitable for public buildings, ensuring that it remains functional and safe over time.

Sustainability and Environmental Impact

- 100% Recyclable

One of the key benefits of 316L stainless steel is its sustainability. Stainless steel is 100% recyclable, which means it can be repurposed at the end of its lifespan without degrading its quality. This makes it an environmentally friendly choice, as it reduces waste and conserves resources. By using 316L stainless steel, architects and developers can contribute to green building initiatives and promote sustainable construction practices. - Durability Leads to Reduced Waste

The longevity of 316L stainless steel further minimizes its environmental impact. Due to its extended lifespan, 316L stainless steel does not require frequent replacements, reducing the overall consumption of raw materials. This reduction in the frequency of replacements helps cut down on construction waste and the need for new materials, contributing to a more sustainable built environment. - Енергоефективність

316L stainless steel is also energy-efficient in the long run. Since it does not require frequent repairs or replacements, there is a significant reduction in the energy consumed during manufacturing, transportation, and installation. Additionally, stainless steel’s ability to withstand the elements means fewer resources are spent on maintaining the structure, further enhancing the building’s overall energy efficiency.

Applications of 316L Stainless Steel in Architecture

- Facade and Cladding Systems

316L stainless steel is often used in architectural facades and cladding due to its durability, aesthetic appeal, and resistance to environmental elements. Its ability to maintain its shine and resist corrosion makes it a go-to material for modern building exteriors, ensuring the longevity of the structure while enhancing its appearance. - Staircases and Handrails

Another common application of 316L stainless steel is in staircases and handrails. Its strength and sleek appearance make it ideal for providing both structural support and aesthetic value. Whether used in private residences, office buildings, or public spaces, stainless steel handrails offer safety and style, enhancing the overall design of the building. - Structural Components

The strength and reliability of 316L stainless steel make it perfect for use in structural components such as columns, beams, and frames. These elements require materials that can handle substantial loads without compromising safety. Stainless steel’s ability to withstand stress and corrosion ensures its effectiveness in such critical applications. - Interior Design Elements

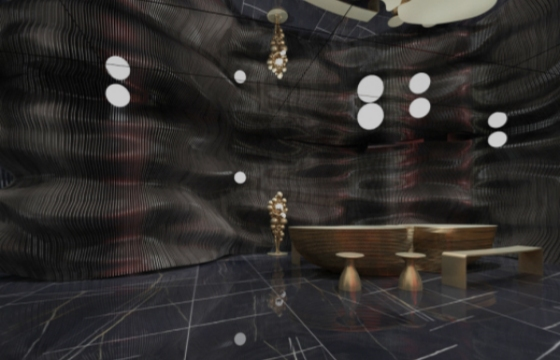

Stainless steel is increasingly being used in interior design elements, from feature walls to custom furniture and decorative elements. Its clean, modern appearance allows it to seamlessly integrate with other materials and design concepts, offering versatility in both commercial and residential projects.

Cost-Effectiveness in the Long Run

- Initial Investment vs. Long-Term Savings

While 316L stainless steel may have a higher initial cost than other materials like aluminum or carbon steel, its long-term savings far outweigh the initial investment. Its durability and resistance to corrosion mean fewer repairs and replacements, resulting in significant savings over time. This makes it a cost-effective solution for both residential and commercial projects in the long run. - Reduced Maintenance and Repair Costs

Stainless steel’s low-maintenance nature further contributes to its cost-effectiveness. Unlike wood or iron, which require regular upkeep to prevent deterioration, 316L stainless steel requires only occasional cleaning to maintain its appearance. Over the years, this significantly reduces maintenance costs and saves on labor and materials. - Increased Property Value

The use of high-quality materials like 316L stainless steel can increase the value of a property. Its durability, modern appearance, and low-maintenance qualities make it a highly desirable feature for both residential buyers and commercial tenants, potentially raising resale and rental values.

Challenges and Considerations

- Higher Initial Cost

The initial expense of 316L stainless steel is higher compared to other materials like aluminum or vinyl. However, this should be viewed as a long-term investment, given its durability and minimal maintenance requirements. - Fabrication and Installation Complexity

Working with stainless steel, particularly 316L, can be more complex than working with other materials. Fabricating and welding stainless steel requires specialized knowledge and equipment, which may increase labor costs. This should be taken into account when planning a project. - Weight and Handling

Stainless steel is heavier than some other materials, such as aluminum, and requires careful handling during transportation and installation. However, the benefits of strength and durability far outweigh this consideration, especially for larger, structural elements.зв'яжіться з нами

Ви можете відвідати наш веб-сайт для отримання додаткової інформації або відвідайте нашу сторінку у Facebook, щоб дізнатися про останні оновлення та основні моменти проекту. Якщо у вас виникли запитання чи пропозиції щодо співпраці, зв’яжіться з нами, і ми з радістю вам допоможемо!