Overview of Stainless Steel in Industry

Stainless steel plays a critical role across various industries, from construction to food processing and medical equipment. Among its different grades, 304 stainless steel stands out due to its excellent strength, corrosion resistance, and cost-effectiveness, making it a go-to material for a wide range of industrial applications. This article delves into the advantages of this grade and explores how it contributes to the performance of various industries.

Purpose of the Article

This article aims to highlight the specific advantages of 304 stainless steel, its key properties, and why it is a preferred material in many industries. By the end, readers will understand how to leverage this material for long-lasting, high-performance results in their industrial projects.

What is 304 Stainless Steel?

- Composition of 304 Stainless Steel: This grade is primarily made of iron, chromium (18%), and nickel (8%). The addition of chromium provides excellent resistance to corrosion, while nickel enhances strength and stability. Other elements, such as manganese and silicon, contribute to the overall performance. It is the combination of these ingredients that gives this alloy its versatility, making it suitable for many industrial applications.

- Stainless Steel Grades and Variants: While 304 is the most commonly used grade, other stainless steel materials are also available for specific purposes. For example, 316 stainless steel, which contains molybdenum, is ideal for environments with high chloride exposure. Though alternatives exist, 304 remains the preferred material for industries requiring a balance between cost, strength, and corrosion resistance.

Key Advantages of 304 Stainless Steel in Industrial Applications

- Corrosion Resistance: One of the standout features of 304 stainless steel is its corrosion resistance, particularly in environments that are exposed to moisture, chemicals, and extreme weather conditions. The chromium content creates a passive protective layer, preventing oxidation and corrosion. This property makes it particularly valuable in industries such as food processing, pharmaceuticals, and marine applications, where equipment is frequently exposed to corrosive substances.

- Strength and Durability:304 stainless steel offers high tensile strength, which makes it suitable for applications that require the material to bear heavy loads. Whether in construction, machinery, or manufacturing equipment, this material ensures long-term durability. For instance, in the building industry, stainless steel components like beams and structural supports are designed to handle immense pressure, ensuring safety and structural integrity.

- Hygienic Properties: 304 stainless steel’s non-porous surface is another significant advantage. Its smooth finish makes it resistant to bacteria and contaminants, which is why it’s widely used in industries like food processing, pharmaceuticals, and medical equipment manufacturing. The material is easy to clean and sanitize, ensuring compliance with stringent hygiene standards, especially in environments where purity and cleanliness are crucial.

- High-Temperature Resistance: This material can withstand high temperatures, withstanding continuous use in temperatures up to 870°C (1600°F), making it suitable for industrial furnaces, exhaust systems, and engine parts. In industries like automotive and aerospace, stainless steel components in exhaust systems and engine parts need to maintain their form and resist thermal stress, ensuring reliability and performance under extreme conditions.

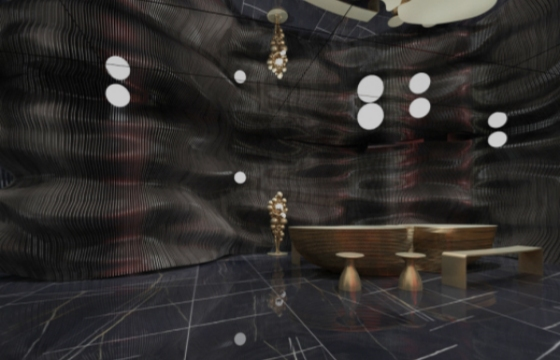

- Aesthetic Appeal: 304 stainless steel is also prized for its aesthetic qualities. Its shiny surface makes it a popular choice for architectural designs and interior decor. In modern construction, it’s often used for building facades, handrails, and decorative panels, contributing to a sleek, contemporary look. The material’s combination of strength and beauty makes it a versatile choice for both functional and decorative applications.

Industrial Applications of 304 Stainless Steel

- Food and Beverage Industry: In the food and beverage industry, this stainless steel grade is commonly used in equipment that comes into direct contact with food, such as storage tanks, piping, and processing machinery. Its resistance to corrosion, ease of cleaning, and hygienic properties make it the preferred choice for ensuring safe and efficient food production. Stainless steel surfaces prevent contamination, ensuring the quality and safety of food products.

- Pharmaceutical and Medical Industries: 304 stainless steel is widely used in pharmaceutical and medical applications, such as in the manufacture of instruments, surgical tools, and even implants. Its non-reactive surface ensures compatibility with drugs and medical procedures, while its resistance to corrosion and contamination makes it ideal for use in sterile environments. In medical devices, this material ensures longevity, safety, and performance.

- Chemical Processing and Manufacturing: In chemical processing, the material’s ability to withstand exposure to harsh chemicals and environments makes it essential. It is commonly used for reactors, heat exchangers, tanks, and pressure vessels. Its durability and corrosion resistance allow it to perform well in industries such as petrochemical, pharmaceutical, and food manufacturing, where chemical interactions are frequent.

- Automotive and Aerospace Industries: The automotive and aerospace industries rely on the strength and durability of this stainless steel for parts that must endure high pressure and extreme environments. It is used in exhaust systems, engine components, and structural parts, providing reliability and performance under harsh conditions. Its resistance to high temperatures and corrosion ensures that critical components remain functional throughout their service life.

- Construction and Architecture: In construction, 304 stainless steel is used in building facades, railings, columns, and other structural elements. Due to its corrosion resistance, it is well-suited for use in outdoor environments. The material’s ability to maintain its appearance and structural integrity over time makes it a popular choice in modern architecture, where both strength and aesthetics are highly valued.

Environmental and Economic Considerations

- Sustainability and Recyclability: 304 stainless steel is 100% recyclable, making it an environmentally friendly option. This feature supports sustainability efforts, as it can be reused without losing its essential properties. As industries increasingly prioritize sustainable materials, this grade of stainless steel stands out as a responsible choice, contributing to a circular economy.

- Cost-Effectiveness: Although the initial cost of 304 stainless steel can be higher than other materials like carbon steel, its long-term value is undeniable. The material’s durability, low maintenance requirements, and extended service life mean that the overall cost of ownership is often lower in the long run. Additionally, its corrosion resistance reduces the need for frequent repairs and replacements, further driving down maintenance costs.

Challenges of Using 304 Stainless Steel

- Cost and Availability: One challenge associated with this material is its relatively high cost compared to alternatives. In situations with tight budgets, it may pose a barrier to some industries. Additionally, depending on market conditions, sourcing and availability might fluctuate. However, the long-term performance benefits usually outweigh the initial cost, especially in applications that require durability and minimal maintenance.

- Impact of Chlorides: A limitation of this stainless steel is that it is prone to corrosion in chloride-rich environments, such as marine settings. In these cases, materials like 316 stainless steel, which contains molybdenum, are better suited due to their enhanced resistance to chloride-induced corrosion. Protective coatings can also be applied to improve the performance of this material in high-chloride environments.

Висновок

Summary of Benefits

304 stainless steel continues to be one of the most widely used and reliable materials in industrial applications. Its corrosion resistance, strength, durability, and high-temperature performance make it an ideal choice for a variety of industries, from food processing to aerospace.

Future Outlook

As industries place greater emphasis on sustainability and high-performance materials, the demand for this stainless steel grade is expected to grow. Innovations in alloy composition and processing techniques may further enhance its capabilities, ensuring that it remains a valuable material for future industrial applications.

Ви можете відвідати наш веб-сайт для отримання додаткової інформації або відвідайте нашу сторінку у Facebook, щоб дізнатися про останні оновлення та основні моменти проекту. Якщо у вас виникли запитання чи пропозиції щодо співпраці, зв’яжіться з нами, і ми з радістю вам допоможемо!