When choosing materials for construction, manufacturing, or any other industrial purpose, understanding the differences between materials is crucial. Steel and stainless steel are two of the most commonly used materials across various industries. Both have unique properties and benefits, but selecting the right one for your specific needs depends on a variety of factors, including cost, strength, durability, and resistance to environmental conditions.

In this article, we will explore the key differences between steel and stainless steel, discuss the advantages and disadvantages of each, and help you determine which material is the best choice for your needs.

What is Steel?

Definition and Composition of Steel

Steel is a widely used material made primarily from iron and carbon. It can also contain other elements such as manganese, silicon, and small amounts of sulfur and phosphorus. The carbon content typically ranges from 0.2% to 2.1%, which affects the strength and hardness of the material.

Types of Steel

- Carbon Steel – Contains higher amounts of carbon, making it stronger but more susceptible to corrosion.

- Alloy Steel – Contains additional elements like chromium, nickel, and molybdenum to enhance specific properties like strength and wear resistance.

- Tool Steel – Specially formulated for tools and machinery due to its hardness and durability.

Common Uses of Steel

Steel is used in a wide variety of industries due to its versatility and strength. In construction, steel is a critical component for building frameworks, beams, and structural supports. It’s also widely used in the automotive industry for car bodies, and in manufacturing for machinery parts.

Pros and Cons of Steel

- Pros:

- Cost-effective: Steel is relatively inexpensive compared to other materials like stainless steel, making it a go-to choice for large-scale projects.

- Strong and durable: Steel is well-known for its strength, making it suitable for structural applications.

- Cons:

- Susceptible to rust and corrosion: Steel needs a protective coating, such as paint or galvanization, to prevent rust when exposed to moisture.

- Maintenance required: Regular maintenance is needed to preserve the integrity of steel, especially in harsh environments.

What is Stainless Steel?

Definition and Composition of Stainless Steel

Stainless steel is a special type of steel that includes a minimum of 10.5% chromium. This high chromium content creates a thin, invisible layer of chromium oxide on the surface, which makes stainless steel resistant to rust and corrosion. Stainless steel also contains varying amounts of nickel, molybdenum, and other elements that enhance its properties.

Different Grades of Stainless Steel

- 304 Stainless Steel: The most common grade, known for its versatility, durability, and resistance to corrosion.

- 316 Stainless Steel: Contains molybdenum, making it more resistant to corrosion, especially in marine environments.

- 410 Stainless Steel: A martensitic steel, which is used for applications requiring high hardness but lower corrosion resistance.

Common Uses of Stainless Steel

Stainless steel is widely used in environments that demand resistance to corrosion and high hygiene standards. This includes kitchens, medical devices, and marine applications. Stainless steel is also popular in architectural designs due to its polished, aesthetically pleasing finish.

Pros and Cons of Stainless Steel

- Pros:

- Corrosion-resistant: Stainless steel does not rust or stain easily, making it ideal for environments exposed to moisture, such as kitchens or bathrooms.

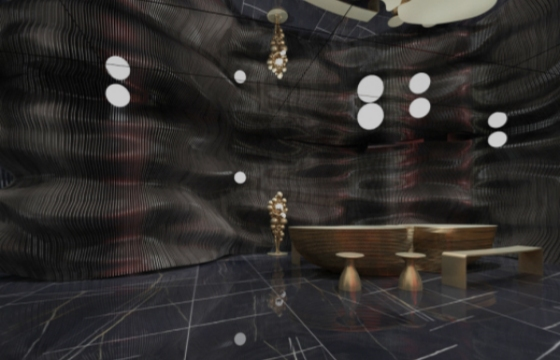

- Aesthetic appeal: Stainless steel has a sleek, modern appearance that adds a polished touch to interiors.

- Easy to clean and maintain: Its smooth surface prevents the buildup of dirt and bacteria, making it perfect for hygienic environments.

- Cons:

- Cost: Stainless steel is generally more expensive than regular steel due to its alloy content.

- Difficult to fabricate: While it is durable, stainless steel can be more challenging to shape and weld, requiring specialized equipment.

Key Differences Between Steel and Stainless Steel

Izturība pret koroziju

One of the most important differences between steel and stainless steel is their corrosion resistance. While steel is prone to rust when exposed to moisture or chemicals, stainless steel’s chromium content naturally forms a protective layer that shields it from rust and staining. This makes stainless steel an ideal choice for kitchens, medical environments, and marine applications, where moisture is present.

Strength and Durability

Both steel and stainless steel are strong materials, but stainless steel is typically more durable, especially in environments with harsh conditions. Stainless steel is ideal for long-term use in industries where materials are exposed to frequent wear and tear, chemicals, and high temperatures.

Cost Comparison

Steel is significantly cheaper than stainless steel. This is one reason why steel is widely used for structural applications where the material won’t be exposed to harsh elements. Stainless steel, on the other hand, is often used when durability and corrosion resistance are essential, making it a higher initial investment but often a better long-term choice.

Estētiskā pievilcība

Stainless steel has a more refined, glossy appearance than steel, making it the material of choice for visible elements like architectural features, kitchen appliances, and decorative elements. Steel tends to be matte and may require finishing to achieve a polished look.

Fabrication and Maintenance

Steel is easier to fabricate due to its lower hardness and simpler composition. It can be welded, cut, and shaped with fewer specialized tools than stainless steel. However, steel requires regular maintenance, such as painting or coating to prevent rust. Stainless steel is more difficult to fabricate but requires less maintenance over time.

Choosing the Right Material for Your Needs

Applications of Steel

Steel is an excellent choice for structural components like beams, frames, and reinforcements in buildings, bridges, and infrastructure. It is also used for vehicle parts, machinery, and heavy-duty equipment. Steel is ideal when the material will not be exposed to moisture or chemicals that would lead to corrosion.

Applications of Stainless Steel

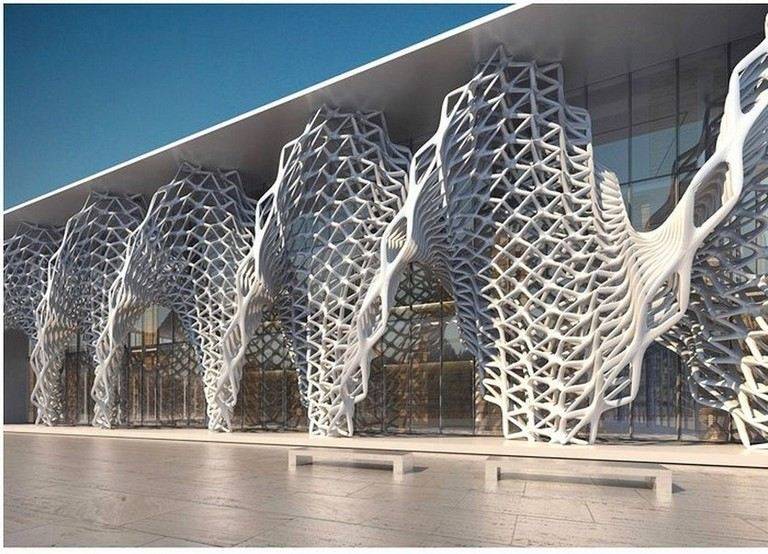

Stainless steel is perfect for applications where corrosion resistance and hygiene are essential. It’s commonly used for kitchen appliances, medical devices, and food processing equipment. It is also used in marine environments, architecture (e.g., railings, staircases), and industrial equipment exposed to chemicals or high temperatures.

Cost-Effectiveness Considerations

When budget is a major concern, steel is often the more economical option. However, for projects that require long-term durability and minimal maintenance, stainless steel may prove to be a better investment over time, as it avoids the need for regular protective coatings and repairs.

Steel and Stainless Steel in Different Industries

Construction Industry

Steel plays a crucial role in the construction industry, where it is used for structural elements like beams, columns, and frames. Stainless steel, however, is often used for decorative elements, railings, and facades that require both strength and aesthetic appeal.

Automotive Industry

Steel is widely used for the body of vehicles, while stainless steel is employed in parts exposed to high temperatures and harsh conditions, such as exhaust systems, trim, and undercarriage components.

Food and Medical Industries

Stainless steel’s resistance to corrosion and ease of cleaning make it the material of choice in both food processing and medical applications. Its hygienic properties make it essential in environments where cleanliness is critical, such as hospital equipment and food storage.

Marine Industry

Stainless steel is essential for applications exposed to saltwater, such as shipbuilding and marine equipment, due to its superior resistance to corrosion in harsh environments. Steel is used for structural elements that are less exposed to moisture.

Secinājums

In conclusion, both steel and stainless steel are valuable materials in various industries. Steel is strong, cost-effective, and suitable for structural applications, while stainless steel offers superior corrosion resistance and aesthetic appeal, making it ideal for environments exposed to moisture, chemicals, and hygiene concerns.

When choosing between steel and stainless steel, consider the specific needs of your project, including the environmental conditions, budget, and long-term durability. Both materials have their advantages, but understanding their properties and differences will ensure that you make the right choice for your application.

sazinieties ar mums

Jūs varat apmeklēt mūsu tīmekļa vietne Lai iegūtu papildinformāciju, vai apmeklējiet mūsu Facebook lapu, lai iegūtu jaunākos atjauninājumus un svarīgākos projektus. Ja jums ir kādi jautājumi vai sadarbības jautājumi, droši sazinieties ar mums, un mēs ar prieku jums palīdzēsim!