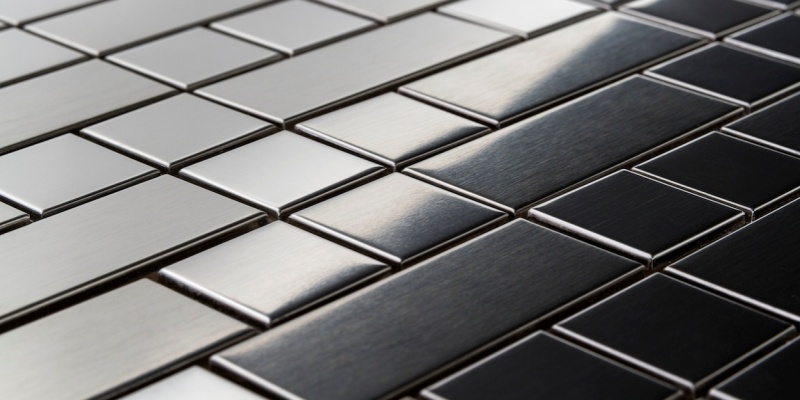

Stainless steel is a foundational material in industries ranging from construction to healthcare. Among its many variants, Material 304 Stainless Steel dominates due to its versatility. This article dives into its properties, compares it with key alternatives (316, 201, 430), and provides actionable insights for selecting the optimal grade.

Material 304 Stainless Steel: Composition and Key Properties

Material 304 Stainless Steel, part of the austenitic family, comprises 18-20% chromium and 8-10% nickel, with trace elements like carbon and manganese. This blend creates a corrosion-resistant, non-magnetic alloy with excellent formability and weldability.

- Chromium’s Role: Forms a passive oxide layer that resists oxidation and staining, even at high temperatures.

- Nickel’s Contribution: Stabilizes the austenitic structure, enhancing ductility and resistance to acidic environments.

Applications:

- Food & Beverage Industry: Used in brewing tanks, dairy processing equipment, and kitchen surfaces due to its hygienic properties.

- Pharmaceuticals: Ideal for sterile environments like surgical tools and MRI machine components.

- Architecture: Cladding, elevator panels, and structural frameworks benefit from its aesthetic polish and weather resistance.

Material 304 Stainless Steel vs. 316: When Corrosion Resistance is Critical

While Material 304 Stainless Steel excels in most environments, Grade 316 outperforms it in aggressive settings:

- Molybdenum Addition: 316 contains 2-3% molybdenum, which combats pitting and crevice corrosion caused by chlorides (e.g., seawater, de-icing salts).

- Performance in Extreme Conditions:

- 304: Suitable for urban architecture or indoor appliances but may corrode in coastal or chemical-heavy areas.

- 316: Preferred for marine hardware, offshore oil rigs, and chemical processing plants.

Case Study: In a seawater desalination plant, 316’s molybdenum content reduces maintenance costs by 30% compared to 304.

Material 304 Stainless Steel vs. 201: Balancing Cost and Durability

Grade 201 is a budget-friendly alternative but sacrifices performance:

- Composition Differences: Replaces some nickel with manganese and nitrogen, lowering cost but reducing corrosion resistance.

- Practical Trade-offs:

- 304: Maintains integrity in humid or mildly acidic environments (e.g., restaurant kitchens).

- 201: Prone to rust in high-moisture settings; better suited for indoor décor or temporary structures.

Example: 201 is widely used in low-cost cookware, but 304 remains standard for high-end appliances requiring longevity.

Material 304 Stainless Steel vs. 430: Magnetic Properties and Applications

Grade 430, a ferritic stainless steel, serves niche roles:

- Magnetism: Unlike non-magnetic 304, 430’s magnetic properties make it useful for induction cooktops or automotive sensors.

- Corrosion Limitations:

- 304: Resists oxidation in wet or acidic conditions (e.g., laboratory equipment).

- 430: Best for dry environments, such as dishwasher interiors or decorative trim.

Cost Insight: 430 costs 20-30% less than 304 but requires protective coatings in outdoor applications.

Advanced Considerations for Material Selection

A. Temperature Tolerance:

- Material 304 Stainless Steel withstands temperatures up to 870°C (intermittent) and 925°C (continuous), ideal for exhaust systems or heat exchangers.

- 316: Performs better in high-temperature corrosive environments (e.g., chemical reactors).

B. Fabrication and Welding:

- 304: Easily welded and formed into complex shapes, making it a go-to for custom architectural designs.

- 430: Prone to warping during welding; requires post-treatment to restore corrosion resistance.

C. Sustainability:

Both 304 and 316 are 100% recyclable, but 304’s widespread use streamlines recycling processes in industries like automotive manufacturing.

How to Choose: Decision Framework

| Factor | 304 | 316 | 201 | 430 |

|---|---|---|---|---|

| Corrosion Resistance | High (moderate environments) | Extreme (chloride-rich) | Low | Moderate (dry) |

| Cost | Mid-range | High | Low | Low |

| Magnetism | Non-magnetic | Non-magnetic | Non-magnetic | Magnetic |

| Best Use Case | Food processing, architecture | Marine, chemical plants | Indoor décor | Automotive, appliances |

결론

Material 304 Stainless Steel remains the gold standard for general-purpose applications, offering a balance of cost, durability, and corrosion resistance. Alternatives like 316 (extreme environments), 201 (budget projects), and 430 (magnetic needs) address specialized requirements. By aligning your project’s environmental exposure, mechanical demands, and budget with these grades’ properties, you can optimize both performance and cost efficiency.

문의하기

당신은 우리의 방문 할 수 있습니다 웹사이트 자세한 내용은 Facebook 페이지를 방문하거나 최신 업데이트와 프로젝트 하이라이트를 확인하세요. 질문이나 협업 문의 사항이 있으면 언제든지 저희에게 연락하세요. 기꺼이 도와드리겠습니다!