Introduction

Stainless steel is widely regarded as one of the most durable and corrosion-resistant materials. Its use spans industries from construction to home appliances, making it a cornerstone of modern manufacturing. However, despite its reputation, questions like “Does stainless steel rust?” persist. While stainless steel is far more resilient than regular steel, certain conditions can lead to rusting. This article dives deep into the myths and facts about stainless steel corrosion, exploring its causes, prevention methods, and why it remains a trusted material.

What Makes Stainless Steel Resistant to Rust?

The Role of Chromium

One of the defining features of stainless steel is its chromium content, typically between 10.5% and 30%. Chromium forms a passive oxide layer on the surface when exposed to oxygen, acting as a shield against moisture and air. This barrier is self-repairing, which makes stainless steel highly resistant to rust.

Other Alloying Elements

In addition to chromium, elements like nickel, molybdenum, and nitrogen enhance the material’s resistance to specific environmental challenges. For example, molybdenum increases resistance to chloride-induced corrosion, making it essential for marine applications.

Why It’s Not 100% Rustproof

Though the protective layer is effective, it is not invincible. Prolonged exposure to extreme conditions—like salt spray or industrial pollutants—can compromise the oxide layer, leading to stainless steel rust under certain circumstances.

Can Stainless Steel Rust? Myths vs. Facts

Myth: All Stainless Steel Is Rustproof

Many assume stainless steel is impervious to rust. However, the reality is more nuanced. While it performs exceptionally well in most environments, improper handling or exposure to harsh elements can lead to corrosion.

Fact: Different Grades Have Varying Resistance Levels

Stainless steel comes in various grades. For instance:

- 304 stainless steel: Versatile and widely used but less resistant to saltwater environments.

- 316 stainless steel: Contains molybdenum, offering superior resistance to chloride corrosion, ideal for marine or coastal areas.

The Balance Between Cost and Performance

Higher-grade stainless steels are more expensive but offer enhanced resistance to rust, making them suitable for demanding applications like chemical plants or offshore platforms.

Common Causes of Stainless Steel Rust

Environmental Factors

Stainless steel can corrode in environments with high salt content, such as coastal regions, or industrial areas with acidic fumes. These elements erode the oxide layer over time.

Improper Cleaning

Using abrasive cleaners or tools can scratch the surface, exposing the underlying metal. For example, steel wool leaves iron particles that accelerate rust formation.

Design Flaws

Poor design, such as crevices or joints that trap moisture, can increase the likelihood of corrosion. Proper engineering minimizes water retention and ensures better drainage.

Case Study: Rust in Marine Environments

In one study, 304 stainless steel components installed near a seaside resort began rusting within a year due to constant exposure to salty air. Switching to 316 stainless steel resolved the issue.

How to Prevent Stainless Steel from Rusting

Choose the Right Grade

For high-corrosion environments, opt for grades like 316 or duplex stainless steel. These grades are specifically designed to handle moisture, salt, and other corrosive agents.

Implement Proper Maintenance

- Clean stainless steel regularly with non-abrasive cloths and pH-neutral detergents.

- Avoid leaving water droplets on the surface, as they can lead to water spots and eventually rust.

Apply Protective Treatments

- Passivation: Removes impurities from the surface, enhancing the natural protective layer.

- Anti-corrosion coatings: Provide an additional shield against harsh conditions.

Practical Tip for Homeowners

If you notice discoloration on stainless steel kitchen appliances, clean them with a mixture of baking soda and water to restore their shine and prevent rust.

Debunking Myths About Stainless Steel Rust

Misconception: Visible Rust Means Poor Quality

Rust on stainless steel doesn’t always indicate low quality. It could be the result of improper handling or environmental exposure. Understanding the cause helps address the issue effectively.

Why Stainless Steel Remains a Trusted Material

Despite occasional rusting, stainless steel is still one of the most reliable materials for construction and household use. Its corrosion resistance, coupled with proper maintenance, ensures decades of performance.

Benefits of Stainless Steel Despite Rust Risks

Unparalleled Durability

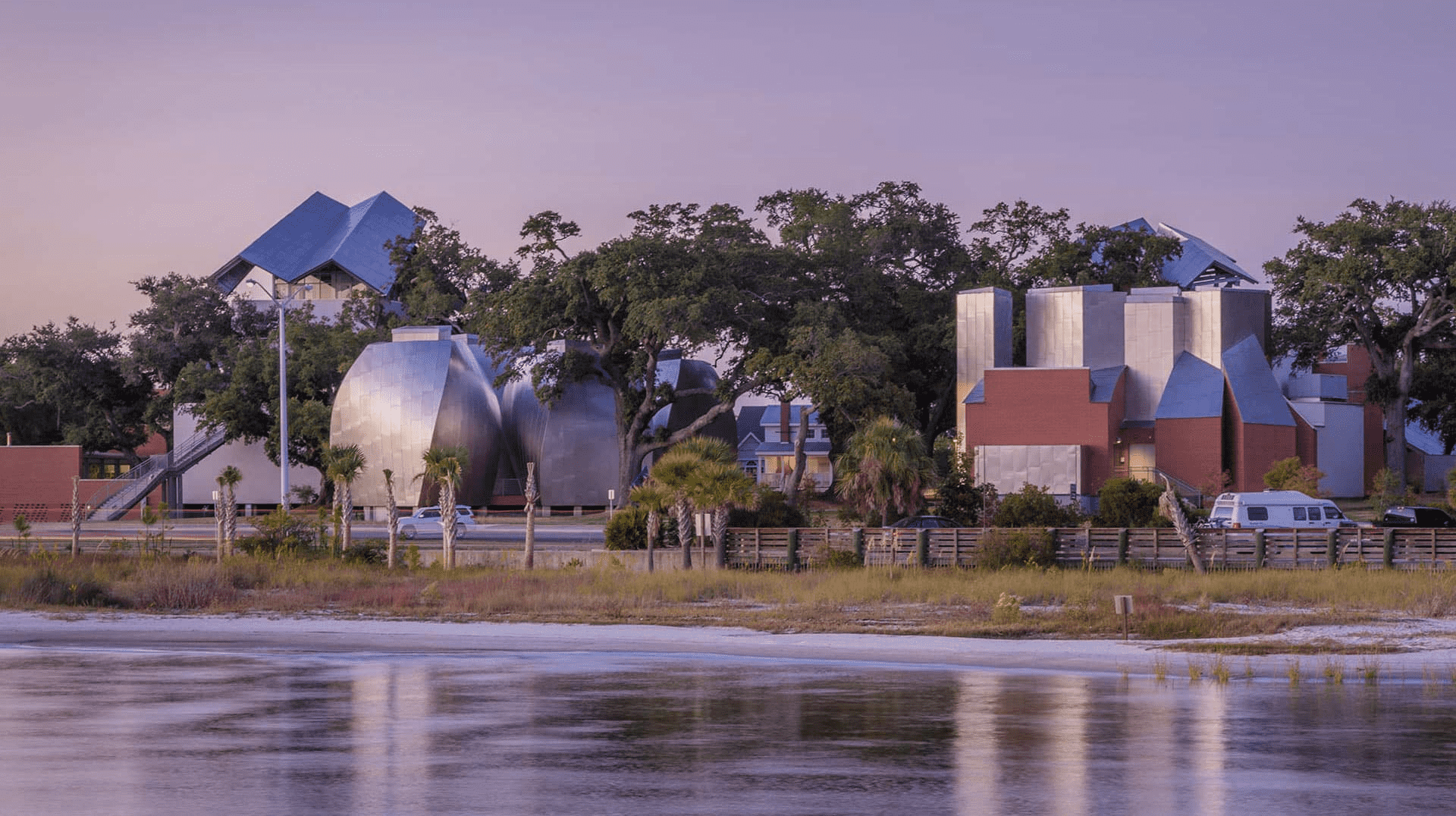

Even when exposed to challenging conditions, stainless steel can outlast other materials. Its ability to maintain structural integrity makes it ideal for both decorative and functional purposes.

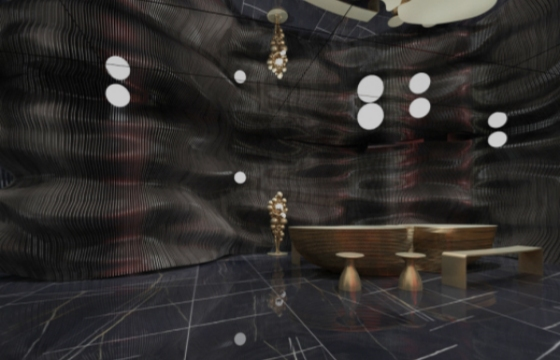

Aesthetic Appeal

Stainless steel’s sleek, modern appearance enhances kitchens, bathrooms, and architectural designs. Proper care ensures it retains its polished look over time.

Sustainability

Stainless steel is 100% recyclable. Even rusted or damaged pieces can be repurposed, contributing to a more sustainable environment.

Industry Insight

According to industry experts, the demand for stainless steel in construction and manufacturing is growing due to its long-term cost-effectiveness and eco-friendly properties.

Kesimpulan

While stainless steel is highly resistant to corrosion, it is not entirely immune. Environmental conditions, improper cleaning, and material grade can lead to rusting. However, understanding these risks and taking preventive measures—such as choosing the right grade and maintaining the material properly—ensures its longevity.

This article sheds light on the true nature of stainless steel rust by debunking myths and providing actionable tips. With the right approach, you can enjoy the benefits of stainless steel for years to come, whether in construction, appliances, or decorative uses.

Hubungi kami

You can visit our website for more information or our Facebook page for the latest updates and project highlights. If you have any questions or collaboration inquiries, feel free to contact us, and we’ll be happy to assist you!