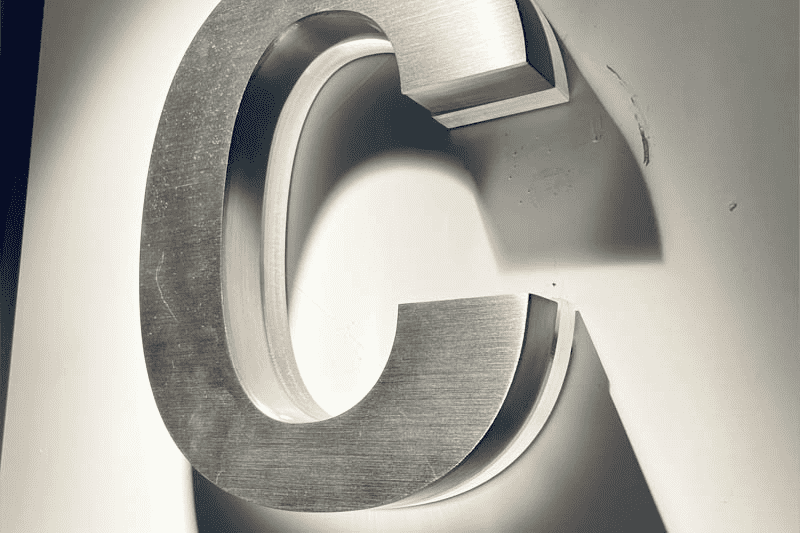

Satin Finish Stainless Steel: Brushed vs Satin

When selecting the perfect stainless steel finish, the choice between brushed and satin isn’t just about aesthetics; it’s about striking the right balance between form and function. Stainless steel, a ubiquitous material in modern design, owes much of its allure to these distinct finishes.

In this article, we embark on “The Ultimate Showdown” between brushed and satin finishes, delving into the nuances that define each. From visual appeal to durability, cost considerations, and even their environmental impact, we’ll help you confidently navigate this stainless steel conundrum.

Understanding Stainless Steel Finishes

Stainless steel finishes are more than just a surface treatment; they play a pivotal role in the aesthetics and functionality of stainless steel products. To truly appreciate the significance of the brushed versus satin finish debate, it’s essential to grasp the fundamentals of stainless steel finishes.

What Are Stainless Steel Finishes?

At its core, stainless steel is a versatile alloy primarily composed of iron, chromium, nickel, and other elements, designed to resist corrosion and staining. However, the final appearance and texture of stainless steel are not solely determined by its composition; it’s heavily influenced by the finishing process applied to its surface.

Why Do Stainless Steel Finishes Matter?

Stainless steel finishes serve multiple purposes:

- Aesthetic Enhancement:

They give stainless steel its distinct visual characteristics, contributing to its modern and sleek appearance. Different finishes can create a variety of textures and reflective qualities, allowing stainless steel to fit seamlessly into diverse design styles. - Functional Attributes:

Beyond aesthetics, finishes can influence the performance of stainless steel products. For instance, the texture and surface hardness can affect how resistant the material is to scratches, fingerprints, and wear and tear.

How Finishes are Achieved

A careful balancing of mechanical and chemical processes produces stainless steel finishes. These treatments work in tandem to transform the surface of stainless steel, meticulously tailoring its texture, appearance, and performance attributes. Here’s a concise overview:

- Mechanical Processes:

These involve abrasion, polishing, or brushing the stainless steel’s surface using abrasive materials or brushes. The direction, pressure, and type of abrasives used can significantly impact the final finish. - Chemical Processes:

Some finishes are achieved by applying chemicals to the stainless steel’s surface. These chemicals can etch, passivate, or coat the steel to create specific appearances and protective layers.

Both brushed and satin finishes fall under these general categories but involve distinct techniques and materials to produce their unique effects. Understanding these processes is essential for making an informed choice between the two finishes.

Brushed Finish Stainless Steel

Stainless steel’s brushed finish, a timeless choice, fits seamlessly into diverse applications. Its distinctive texture and appearance imbue stainless steel items with elegance and character. In this section, we’ll explore the allure of brushed finish stainless steel in greater detail.

Characteristics of Brushed Finish Stainless Steel

The brushed finish stainless steel is defined by its matte appearance with subtle, parallel lines that run across the surface. These lines are a result of the manufacturing process, where the steel undergoes abrasive brushing. Here are some key characteristics of brushed finish stainless steel:

- Texture:

The most distinctive feature of brushed stainless steel is its textured surface. The brushing process creates tiny grooves or “grain” on the metal’s surface, giving it a tactile and visually appealing texture. - Appearance:

Brushed stainless steel has a subdued, non-reflective appearance that diffuses light rather than reflecting it. This matte finish provides a sleek and contemporary aesthetic that complements various design styles. - Scratch Resistance:

While not entirely impervious to scratches, brushed stainless steel is less prone to visible scratches and scuffs compared to polished finishes. The texture helps to conceal minor blemishes.

Proces proizvodnje

Creating the brushed finish entails the use of abrasive materials to impart that distinct texture onto the stainless steel surface. This process generally encompasses the following essential steps:

- Preparation:

The stainless steel surface is cleaned and smoothed to remove any imperfections or irregularities. - Brushing:

Abrasive materials such as sandpaper or abrasive belts are applied to the surface in a consistent, linear pattern. This brushing action creates a distinctive grain pattern. - Final Finish:

After brushing, the stainless steel may undergo additional processes to refine the finish and ensure uniformity.

Common Applications

Brushed finish stainless steel finds its way into numerous applications, both functional and decorative. Some of the common uses include:

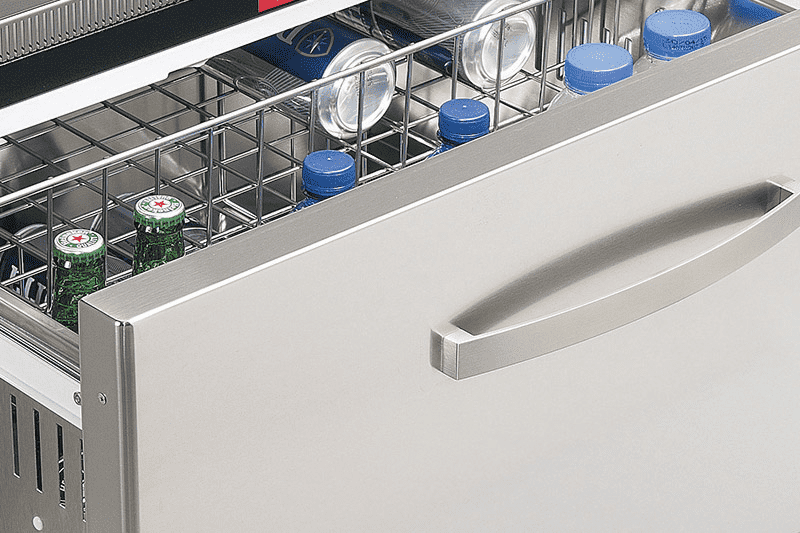

- Kitchen Appliances:

Many modern kitchen appliances, such as refrigerators, dishwashers, and ovens, feature brushed stainless steel surfaces for their elegant and modern appearance. - Furniture and Decor:

It’s a popular choice for furniture, fixtures, and architectural elements like handrails, balusters, and elevator panels, adding a touch of sophistication to interior spaces. - Automotive Trim:

In the automotive industry, brushed stainless steel is often used for trim pieces and accents, enhancing the overall design of vehicles. - Commercial and Industrial Settings:

Its durability and resistance to visible wear make it suitable for use in commercial kitchens, laboratories, and industrial settings.

Brushed finish stainless steel effortlessly marries style and utility, offering versatility to those in pursuit of a contemporary, long-lasting stainless steel surface. In the following section, we’ll delve into the attributes and uses of satin finish stainless steel, ensuring a thorough comparative analysis.

Satin Finish Stainless Steel

In stainless steel finishes, the satin finish stands out as a beloved and adaptable choice, deserving of its moment in the spotlight. Thanks to its distinctively smooth and velvety surface, this finish flawlessly blends aesthetics with utility, earning itself a prized spot in a wide range of applications.

Characteristics of Satin Finish Stainless Steel

Satin finish stainless steel is renowned for its understated elegance and timeless appeal. Here are some of its defining characteristics:

- Smooth and Lustrous Texture:

The hallmark of satin finish stainless steel is its smooth and slightly reflective surface. It lacks the pronounced texture and graininess of brushed finish stainless steel, resulting in a more refined appearance. - Even Grain Patterns:

Unlike the distinctive parallel lines of brushed stainless steel, satin finish typically exhibits a more uniform and subtle grain pattern. This gives it a consistent, low-key sheen that adds a touch of sophistication to any setting. - Low Light Reflection:

Satin finish stainless steel is designed to reduce glare and light reflection, making it an ideal choice for spaces where a subdued and comfortable ambiance is desired.

Manufacturing Process and Techniques

To achieve the satin finish, stainless steel undergoes a multi-step process:

- Initial Grinding:

The stainless steel surface is initially ground to remove any imperfections or irregularities. This creates a smooth base for the satin finish. - Sanding and Buffing:

The surface is then meticulously sanded with fine abrasive materials, followed by buffing with soft materials like cloth or abrasive pads. This process refines the surface and imparts its characteristic silky texture. - Final Cleaning:

The stainless steel is thoroughly cleaned to remove any residual particles or compounds, ensuring a pristine finish.

Applications of Satin Finish Stainless Steel

Satin finish stainless steel’s versatility extends to various industries and applications:

- Architectural Elements:

It’s a popular choice for architectural projects, including handrails, balustrades, and façades, where a sleek, modern appearance is desired. - Automotive Industry:

Satin finish stainless steel can be found in car interiors, trim, and exhaust systems due to its aesthetic appeal and resistance to corrosion. - Home Appliances:

High-end kitchen appliances often feature satin finish stainless steel surfaces, providing a sophisticated look that complements modern kitchen designs. - Furniture and Fixtures:

Satin finish stainless steel is used in the production of furniture, lighting fixtures, and bathroom accessories, enhancing both aesthetics and durability.

Satin stainless steel’s refined, glare-free surface effortlessly marries elegance and functionality. It elevates aesthetics while guaranteeing longevity and corrosion resistance, making it ideal for architectural, automotive, and household applications, embracing the beauty of simplicity.

The Aesthetics Comparison

When it comes to choosing between brushed and satin finish stainless steel, aesthetics play a pivotal role. These two finishes offer distinct visual characteristics that can significantly impact the overall look of your space or product. Let’s delve into a detailed comparison of their aesthetics:

Brushed Finish Stainless Steel

Brushed stainless steel’s allure lies in its distinctive texture and subtle luster. Picture the steel’s surface delicately brushed with fine abrasives, yielding a uniform pattern of delicate lines or “grain.” This textural quality not only enhances visual intrigue but also offers a tactile appeal appreciated by many.

The brushed finish exudes sophistication and industrial chic, perfect for modern and contemporary designs. Its fine lines both diffuse reflections and conceal minor imperfections, making it ideal for high-traffic areas like kitchen appliances, sinks, and cabinet hardware.

Satin Finish Stainless Steel

Satin finish stainless steel distinguishes itself with its smoother, more uniform surface in contrast to brushed stainless steel. This finish achieves an elegant equilibrium, offering a refined blend of understated luster and a subtle, sophisticated sheen.

In contrast, satin finish stainless steel boasts a smoother, more uniform surface than its brushed counterpart, achieving a delicate equilibrium between a subdued luster and a gentle sheen, culminating in an understated yet truly elegant aesthetic.

Comparing the Aesthetics

Now, let’s compare these two aesthetics:

- Texture:

Brushed finish stainless steel showcases a textured, linear pattern, while satin finish is smoother and more uniform. - Shine:

Brushed stainless steel has a more subdued shine, whereas a satin finish exhibits a soft, gentle luster. - Style:

The brushed finish leans towards a modern, industrial look, while a satin finish offers a versatile and timeless elegance. - Visibility of Imperfections:

A brushed finish can better conceal minor scratches and blemishes due to its textured surface, while a satin finish may show them more prominently.

The decision between brushed and satin stainless steel hinges on personal taste and the desired aesthetic. Think about your space’s decor, lighting, and ambiance. Both finishes bring distinctive charm, whether for a modern kitchen or an elegant architectural design.

Durability and Maintenance

When it comes to stainless steel finishes, durability and ease of maintenance are paramount considerations. Let’s delve into how brushed and satin finishes stack up in these crucial aspects. Durability ensures longevity, while ease of maintenance simplifies daily care, making your choice a vital part of your project’s success.

Durability

Brushed Finish Stainless Steel

The brushed finish boasts impressive durability. Its textured surface not only enhances aesthetics but also enhances resistance to visible scratches and scuffs. This is particularly beneficial in high-traffic areas or applications prone to friction and contact.

Satin Finish Stainless Steel

Satin finish stainless steel is renowned for its durability. Despite lacking the textured surface of a brushed finish, it exhibits impressive resilience against wear and tear. Its capacity to retain a smooth, unblemished appearance over time underscores its robustness.

Maintenance

Brushed Finish Stainless Steel

Brushed finish stainless steel excels at concealing minor flaws and smudges, thanks to its textured surface. It’s particularly well-suited for areas such as kitchen appliances and fixtures, where the visibility of fingerprints, water spots, and light scratches is a common concern.

Satin Finish Stainless Steel

Satin finish stainless steel boasts a smoother surface that’s a breeze to maintain. It resists dirt buildup better than other finishes, requiring only a gentle wipe with a damp cloth or mild cleaner. This convenience extends its suitability for architectural and outdoor applications.

Comparing Maintenance

Both finishes offer distinct maintenance benefits. Brushed finish conceals wear and tear effectively, while satin finish simplifies cleaning. Your decision hinges on the application’s demands and your preferred maintenance commitment.

Brushed and satin finish stainless steel each brings distinct benefits in durability and maintenance. Your choice should harmonize with your needs, style, and maintenance commitment. With proper care, your stainless steel surfaces will retain their allure for years to come.

Application-specific Considerations

When deciding between brushed and satin finish stainless steel, it’s vital to weigh their suitability for specific applications and environments. Each finish boasts unique attributes tailored to distinct purposes. Let’s explore application-specific factors to guide your decision:

Kitchen and Home Appliances

- Brushed Finish:

Brushed stainless steel is a popular choice for kitchen appliances like refrigerators, ovens, and dishwashers. Its textured surface not only adds a modern aesthetic but also helps conceal minor scratches and fingerprints, which are common in busy kitchens. - Satin Finish:

Satin stainless steel can also be used for appliances but is often favored for its sleek, smooth appearance. It’s easier to clean and maintain, making it an excellent option for homeowners who prioritize a pristine look in their kitchen.

Architectural Elements and Interior Design

- Brushed Finish:

This finish is a standout choice for architectural elements such as handrails, balustrades, and elevator panels. Its textured surface provides a unique tactile experience and adds a touch of sophistication to interior spaces. - Satin Finish:

Satin stainless steel is a versatile option in architectural design, offering a contemporary and clean appearance. It’s frequently used for fixtures like bathroom faucets, door handles, and kitchen cabinet hardware.

Commercial and Industrial Settings

- Brushed Finish:

In industrial settings, brushed stainless steel’s ability to hide minor wear and tear makes it a go-to choice for equipment and machinery surfaces. It’s also well-suited for high-traffic areas in commercial spaces. - Satin Finish:

Satin stainless steel’s corrosion resistance and smooth surface make it suitable for applications where hygiene is critical, such as in the food processing industry or healthcare facilities.

Automotive Industry

- Brushed Finish:

Brushed stainless steel is often used in the automotive industry for trim pieces and accents. Its ability to resist abrasion and maintain its appearance under various weather conditions makes it a reliable choice for vehicle exteriors.

Outdoor Installations

- Brushed Finish:

When it comes to outdoor use, brushed stainless steel may be preferred due to its ability to mask scratches and imperfections. It’s an excellent option for outdoor furniture, railings, and decorative elements. - Satin Finish:

Satin stainless steel can also be used outdoors, especially in architectural projects. Its smooth surface is relatively easy to clean, making it suitable for areas exposed to the elements.

When it comes to selecting between brushed and satin finish stainless steel, your project’s unique needs and design preferences should guide your decision. Evaluating factors such as functionality, durability, and maintenance ensures both a visually appealing and high-performing choice for your specific application.

Razmatranje troškova

When embarking on a project or renovation involving stainless steel, budget is a significant factor that often influences decision-making. Understanding the cost differences between brushed and satin finish stainless steel can be pivotal in making the right choice for your specific needs.

Brushed Finish Stainless Steel

The brushed stainless steel finish typically offers a budget-friendly option compared to satin. This cost-effectiveness is attributed to the manufacturing process; mechanical brushing, being less labor-intensive, creates the texture, thus lowering production expenses.

Brushed stainless steel finds widespread use in everyday appliances and fixtures, frequently produced on a large scale. This production scale enhances its affordability, making it an excellent choice for budget-conscious projects without sacrificing quality or aesthetics.

Satin Finish Stainless Steel

However, satin finish stainless steel often comes at a slightly higher price point compared to brushed. This cost discrepancy arises from the intricate manufacturing process involved in achieving the satin finish, which includes labor-intensive steps like grinding and polishing.

Satin finish stainless steel finds its niche in settings that prioritize sleek elegance, like upscale kitchen appliances and architectural features. The higher cost aligns with its exceptional aesthetics, justifying the investment for its elevated visual allure.

Balancing Cost and Aesthetics

When considering cost, it’s crucial to weigh your budget against your aesthetic preferences and the intended use of the stainless steel. While a brushed finish is more budget-friendly, a satin finish might be worth the investment if it aligns with your design vision and project goals.

Consider that your decision isn’t just about expenses; it’s equally about attaining your desired aesthetics and functionality. Weigh your priorities thoughtfully to find the finish that strikes the ideal balance between budget and visual impact for your project.

Sustainability and Environmental Impact

As we delve into the comparison between brushed and satin finish stainless steel, it’s vital to weigh not just aesthetics and functionality but also the burgeoning concern of sustainability in our modern world. Let’s explore their environmental implications.

Brushed Finish Stainless Steel

Brushed finish stainless steel, known for its distinctive texture, tends to boast a marginally superior sustainability track record when stacked up against alternative finishes. The reasons behind this advantageous edge are worth exploring:

- Longevity:

Stainless steel, in general, is known for its durability and longevity. This means that products with brushed finishes are less likely to wear out or require replacement, reducing the overall environmental impact. - Recyclability:

Stainless steel is highly recyclable. When products reach the end of their life cycle, they can be recycled into new stainless steel products, reducing the demand for virgin materials. - Energy-efficient production:

The manufacturing process for brushed finishes typically consumes less energy compared to some other finishes, which can be energy-intensive.

Satin Finish Stainless Steel

Satin-finish stainless steel offers several sustainability advantages akin to its brushed counterpart. However, specific considerations set them apart:

- Durability and Recyclability:

Like brushed finish, satin finish stainless steel is durable and recyclable, contributing to a sustainable lifecycle. However, the specific manufacturing processes for satin finishes can vary, affecting their environmental footprint. - Maintenance:

Satin finish may require slightly more maintenance than brushed to preserve its appearance. Excessive or improper cleaning can increase the use of cleaning agents and water, impacting sustainability.

Choosing Sustainability

When it comes to sustainability, the key takeaway is that both brushed and satin finish stainless steel offer eco-friendly attributes due to the inherent qualities of stainless steel itself. Your choice should also consider factors such as the product’s intended use and the manufacturer’s practices.

- Opt for high-quality stainless steel products that are built to last.

- Consider the reputation and environmental commitments of the manufacturer.

- Practice responsible maintenance to prolong the life of your stainless steel items and minimize environmental impact.

The sustainability distinctions between brushed and satin stainless steel are subtle, but stainless steel, with its inherent eco-friendliness, aligns well with environmentally aware consumers. Elevate sustainability through mindful product choices, responsible usage, and eco-friendly disposal practices.

Making the Right Choice

After delving into the subtleties of brushed and satin finishes in stainless steel, it’s crucial to align your choice with your unique requirements. Consider aesthetics, practicality, location, budget, and complementary elements for the ideal finish:

Aesthetic Preferences

Pause and ponder your personal style and space’s design. Are you enticed by the cozy texture of brushed stainless steel, or does the gentle, consistent gleam of satin appeal to you? Your aesthetic inclinations are pivotal in your choice.

Functionality

Think about your application’s practical needs. Satin finish conceals fingerprints and minor scratches, ideal for a clean, unblemished look. In contrast, brushed stainless steel introduces texture and character, perfect for those seeking a unique aesthetic touch.

Location and Use

Consider the stainless steel’s intended location. Brushed finishes are popular in kitchens and bathrooms for their smudge-hiding prowess, while satin finishes are preferred for architectural elements such as handrails and signage, influenced by environmental factors.

Budget Constraints

When making your choice, don’t forget your budget. Brushed stainless steel can sometimes be pricier because of the extra labor needed for its textured finish. So, consider your budget limits and seek cost-effective alternatives in your chosen finish.

Long-Term Maintenance

Consider the level of maintenance you’re willing to commit to. While both finishes are relatively low-maintenance, satin finishes may require slightly less effort in terms of cleaning and upkeep. Think about your tolerance for regular maintenance tasks.

Project Specifics

Each project has its distinct needs. If you’re uncertain about the ideal finish, consider consulting professionals or tapping into the wisdom of seasoned contractors and designers. Their expertise can provide invaluable guidance tailored to your situation.

Complementary Elements

Contemplate how stainless steel will blend with your space. Assess the color schemes, materials, and finishes already present. Ensure your stainless steel choice complements the overall design and ambiance seamlessly.

Environmental Considerations

If you’re passionate about sustainability, it’s worth exploring the environmental impact of these finishes. Certain production techniques and materials might be more eco-friendly, aligning better with your green values.

Ultimately, your decision hinges on personal taste and project needs. It’s more than aesthetics; it’s about striking the ideal form-function equilibrium. Take your time, ponder these factors, and follow your instincts. Your choice – be it satin’s subtle elegance or brushed steel’s textured allure – shapes your space’s beauty and functionality.

Conclusion

Choosing between brushed and satin finish stainless steel goes beyond aesthetics; it’s about striking a balance between style and practicality. Brushed steel radiates classic texture, while satin exudes modern elegance. Be mindful of your application, upkeep, and budget when deciding.

Whether you’re drawn to the cozy charm of brushed or the sleek elegance of satin, both provide lasting durability and flexibility. We trust this guide aids your decision, elevating your project’s look and utility. Please share your thoughts or queries in the comments; we’re here to help!