What is 316S Stainless Steel?

316S stainless steel is a low-carbon version of 316 stainless steel, belonging to the austenitic family of stainless steels. Known for its exceptional corrosion resistance and strength, it is widely used in demanding environments, including marine, medical, and chemical industries.

Why Focus on Composition and Strength?

Understanding the composition and mechanical properties of 316S stainless steel is crucial for selecting the right material for specific applications. These properties determine its performance, durability, and cost-effectiveness in various industries.

Composition of 316S Stainless Steel

Primary Elements

- Iron (Fe): The base metal that constitutes most of the 316S.

- Chromium (Cr): Makes up about 16-18% of the alloy, forming a passive oxide layer that protects against rust.

- Nickel (Ni) enhances ductility and toughness while improving corrosion resistance. It is typically present at 10-14%.

- Molybdenum (Mo): Found at 2-3%, molybdenum significantly increases resistance to pitting and crevice corrosion in chloride-rich environments.

Low Carbon Content (Lin 316S)

The “L” stands for low carbon, with a maximum carbon content of 0.03%. This reduces the risk of carbide precipitation during welding, making 316S ideal for applications requiring strong welds without compromising corrosion resistance.

Trace Elements

Small amounts of elements like manganese, silicon, and phosphorus improve machinability and stability during processing.

Mechanical Strength of 316S Stainless Steel

Tensile Strength

316S offers a tensile strength of approximately 485 MPa, making it suitable for applications that require a balance of strength and flexibility.

Yield Strength

With a yield strength of around 170 MPa, 316S can withstand moderate stresses without permanent deformation.

Ductility and Toughness

The alloy maintains excellent ductility, allowing it to stretch and bend under load without breaking. Its toughness ensures performance under impact and extreme conditions.

Impact of Temperature

316S retains its strength in both high and low temperatures, making it versatile for applications in cryogenic and heat-intensive environments.

Corrosion Resistance Properties

Resistance to General Corrosion

The high chromium and molybdenum content provides a robust defense against oxidation and rust, even in wet or humid environments.

Performance in Aggressive Environments

316S is particularly effective in resisting corrosion from harsh chemicals, acids, and saline solutions, making it a preferred choice for chemical processing and marine applications.

Pitting and Crevice Corrosion Resistance

The addition of molybdenum enhances its resistance to localized forms of corrosion, such as pitting, which can occur in chloride-rich environments like seawater.

Applications of 316S Stainless Steel

Industrial Applications

316S is extensively used in industries such as oil and gas, petrochemicals, and power plants, where its corrosion resistance ensures reliability.

Medical and Pharmaceutical Uses

Its biocompatibility makes it ideal for surgical instruments, implants, and pharmaceutical processing equipment.

Industrija hrane i pića

316S’s hygienic properties and resistance to food acids make it a standard material for food processing and storage equipment.

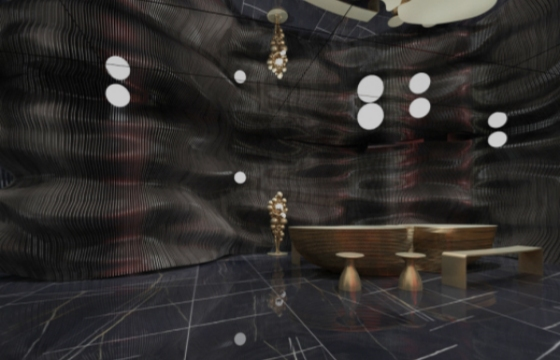

Architectural and Consumer Products

The alloy’s aesthetic appeal and durability make it a popular choice for outdoor railings, high-end jewelry, and watches.

Benefits of 316S Stainless Steel

Longevity and Durability

The alloy’s resistance to corrosion and wear ensures a long service life, even in harsh conditions.

Ease of Fabrication

316S is easy to weld, form, and machine, making it versatile for a wide range of manufacturing processes.

Low Maintenance Requirements

Its corrosion resistance minimizes the need for regular cleaning and maintenance, reducing overall lifecycle costs.

Limitations of 316L Stainless Steel

Razmatranje troškova

The addition of nickel and molybdenum makes 316L more expensive than other stainless steel grades like 304.

Not Ideal for High-Stress Applications

For applications requiring extreme strength, alternative materials such as duplex stainless steel or titanium may be better suited.

Susceptibility to Stress Corrosion Cracking

In certain high-stress, high-temperature, and chloride-rich environments, 316S may experience stress corrosion cracking.

Conclusion

Summary of Composition and Strength

316S stainless steel offers a unique combination of corrosion resistance, mechanical strength, and versatility, making it a top choice across industries.

Why 316S Stainless Steel is a Reliable Choice

Its durability, ease of fabrication, and adaptability to extreme environments justify its popularity for a wide range of applications.

contact us

Možete posjetiti našu web stranica for more information or our Facebook page for the latest updates and project highlights. If you have any questions or collaboration inquiries, feel free to contact us, and we’ll be happy to assist you!